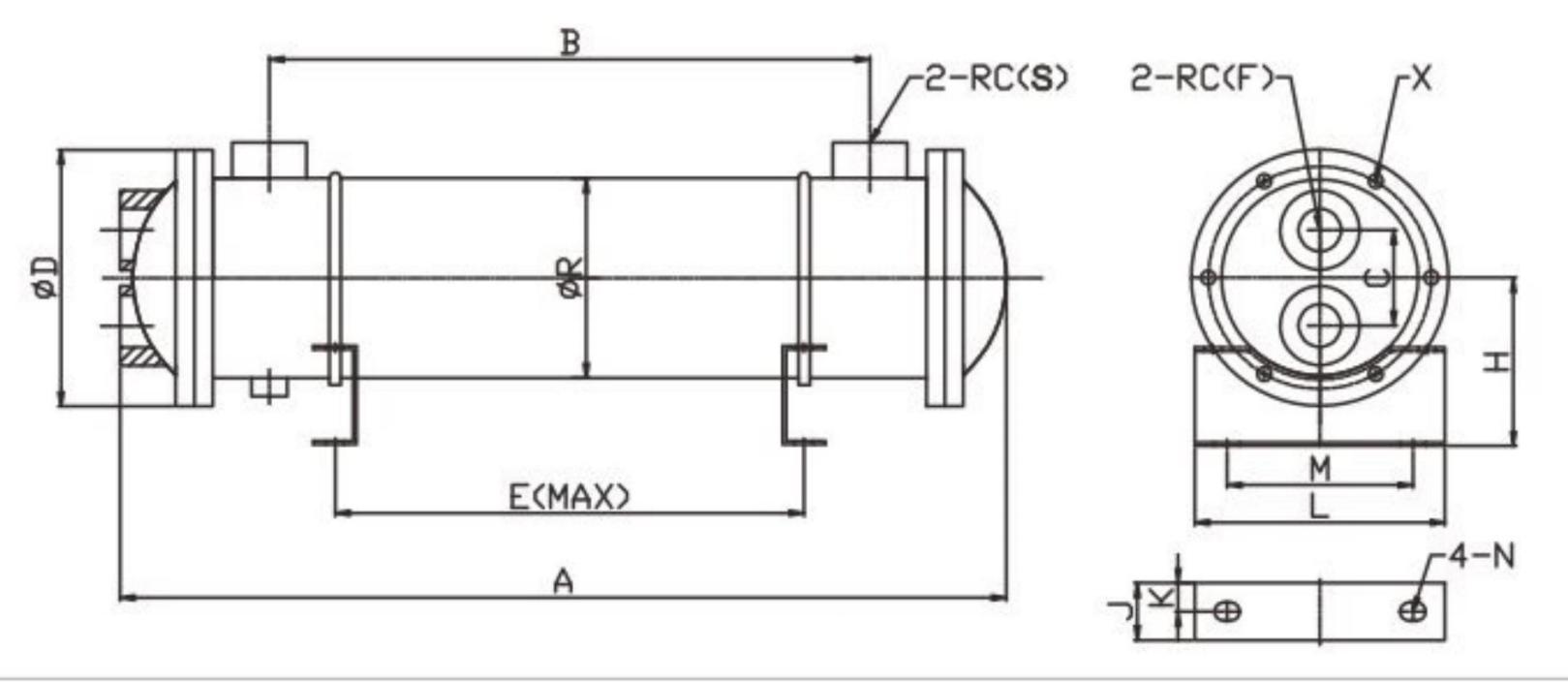

| Model | A (mm) | B (mm) | C (mm) | R (mm) | D (mm) | E (mm) | H (mm) | J (mm) | K (mm) | L (mm) | M (mm) | N | X | S | F | Flow (lpm) |

| OR-60 | 450 | 305 | 55 | 89 | 120 | 210 | 84 | 34 | 13 | 95 | 57 | 11-20Lumbar holes | 4-M8 | 3/4'' | 3/4'' | 60 |

| OR-100 | 555 | 390 | 60 | 114 | 150 | 280 | 104 | 30 | 13 | 150 | 95 | 11-20Lumbar holes | 6-M8 | 3/4'' | 3/4'' | 100 |

| OR-150 | 575 | 380 | 70 | 140 | 180 | 280 | 118 | 30 | 13 | 175 | 130 | 11-20Lumbar holes | 6-M8 | 1¼'' | 1'' | 150 |

| OR-250 | 780 | 580 | 70 | 140 | 180 | 480 | 118 | 30 | 13 | 175 | 130 | 11-20Lumbar holes | 6-M8 | 1¼'' | 1'' | 250 |

| OR-350 | 1175 | 985 | 70 | 165 | 180 | 885 | 118 | 30 | 13 | 175 | 130 | 11-20Lumbar holes | 6-M8 | 1¼'' | 1'' | 350 |

| OR-600 | 1175 | 950 | 110 | 165 | 215 | 760 | 142.5 | 30 | 13 | 203 | 160 | 14-17Lumbar holes | 8-M8 | 2'' | 1¼'' | 600 |

| OR-800 | 1700 | 1470 | 110 | 165 | 215 | 1280 | 142.5 | 30 | 13 | 203 | 160 | 14-17Lumbar holes | 8-M8 | 2'' | 1¼'' | 800 |

| OR-1000 | 2140 | 1890 | 110 | 165 | 215 | 1700 | 142.5 | 30 | 13 | 203 | 160 | 14-17Lumbar holes | 8-M8 | 2'' | 1¼'' | 1000 |

| OR-1200 | 2530 | 2270 | 110 | 165 | 215 | 2080 | 142.5 | 30 | 13 | 203 | 160 | 14-17Lumbar holes | 8-M8 | 2'' | 1¼'' | 1200 |

1. The foundation of the cooler must be enough to prevent the equipment from sinking, and there should be enough space at the end of the fixed hole pan head cover. In order to pull out the tube bundle from the shell, the equipment should be installed according to the hoisting specification. After the level is aligned, tighten the anchor screws to connect the inlet and outlet pipes of the cold and hot medium. 2. The air in the cavity should be exhausted before the cooler is started to improve the heat transfer efficiency. The steps are as follows: 1) Loosen the vent plugs on the hot and cold medium ends, and close the medium discharge valve; 2) Slowly open the water inlet valve of the hot and cold medium until the hot and cold medium overflows from the air vent, then tighten the air vent plug and close the water inlet valve. 3. When the water temperature rises by 5-10°C, open the water inlet valve of the cooling medium (Note: Do not open the water inlet valve quickly. When a large amount of cooling water flows through the cooler, it will cause a long-term formation on the surface of the heat exchanger. The "supercooled layer" with poor thermal conductivity of the layer), and then open the inlet and outlet valves of the heat medium to make it in a flowing state, and then pay attention to adjusting the flow rate of the cooling medium to keep the heat medium at the best operating temperature. 4. If galvanic corrosion occurs on one side of the cooling water, a zinc rod can be installed at the designated position. 5. Before the dirty medium passes through the cooler, a filter device should be provided. 6. The pressure of the cooled medium should be greater than the pressure of the cooling medium. 1. CNC welding is used in the welding place, the welding joint is more round and full, and the appearance is more beautiful and durable. 2. The direction and angle of assembly can be changed at will, and the feet can be directly welded to any position of the mother machine or oil tank, which is convenient and simple. 3. Water inlet and outlet - good sealing performance, after 12 hours of pressure maintenance. 4. Oil inlet and outlet - good sealing, not easy to leak oil.

1. The foundation of the cooler must be enough to prevent the equipment from sinking, and there should be enough space at the end of the fixed hole pan head cover. In order to pull out the tube bundle from the shell, the equipment should be installed according to the hoisting specification. After the level is aligned, tighten the anchor screws to connect the inlet and outlet pipes of the cold and hot medium. 2. The air in the cavity should be exhausted before the cooler is started to improve the heat transfer efficiency. The steps are as follows: 1) Loosen the vent plugs on the hot and cold medium ends, and close the medium discharge valve; 2) Slowly open the water inlet valve of the hot and cold medium until the hot and cold medium overflows from the air vent, then tighten the air vent plug and close the water inlet valve. 3. When the water temperature rises by 5-10°C, open the water inlet valve of the cooling medium (Note: Do not open the water inlet valve quickly. When a large amount of cooling water flows through the cooler, it will cause a long-term formation on the surface of the heat exchanger. The "supercooled layer" with poor thermal conductivity of the layer), and then open the inlet and outlet valves of the heat medium to make it in a flowing state, and then pay attention to adjusting the flow rate of the cooling medium to keep the heat medium at the best operating temperature. 4. If galvanic corrosion occurs on one side of the cooling water, a zinc rod can be installed at the designated position. 5. Before the dirty medium passes through the cooler, a filter device should be provided. 6. The pressure of the cooled medium should be greater than the pressure of the cooling medium. 1. CNC welding is used in the welding place, the welding joint is more round and full, and the appearance is more beautiful and durable. 2. The direction and angle of assembly can be changed at will, and the feet can be directly welded to any position of the mother machine or oil tank, which is convenient and simple. 3. Water inlet and outlet - good sealing performance, after 12 hours of pressure maintenance. 4. Oil inlet and outlet - good sealing, not easy to leak oil.Metallurgical and chemical industry

Injection Engineering Machinery

Light Industry Textiles

The new high-efficiency tubular oil cooler developed based on global relevant data is suitable for hydraulic lubrication systems in metallurgy, mining, chemical industry, electric power, machine tools, light industry, plastics and other industries to cool the working medium to the specified temperature.1. Before the dirty medium passes through the cooler, there should be a filter. 2. It is best to install it in a separate circulating loop, because the pressure (tail end) is small. 3. When working, both circulation loops need to be exhausted to achieve high efficiency and avoid rust in the loop. 4. The cold medium is connected first, and then the hot medium is connected to achieve high efficiency and avoid corrosion of the circuit. 5. The pressure of the cooled medium should be greater than that of the cooling medium. 6. The cooling water is usually fresh water (special order is required when cooling with sea water) 7. Regularly exhaust and clean at intervals. 8. In the cold season, and the cooler is not working, the water must be drained to avoid freezing.

The new high-efficiency tubular oil cooler developed based on global relevant data is suitable for hydraulic lubrication systems in metallurgy, mining, chemical industry, electric power, machine tools, light industry, plastics and other industries to cool the working medium to the specified temperature.1. Before the dirty medium passes through the cooler, there should be a filter. 2. It is best to install it in a separate circulating loop, because the pressure (tail end) is small. 3. When working, both circulation loops need to be exhausted to achieve high efficiency and avoid rust in the loop. 4. The cold medium is connected first, and then the hot medium is connected to achieve high efficiency and avoid corrosion of the circuit. 5. The pressure of the cooled medium should be greater than that of the cooling medium. 6. The cooling water is usually fresh water (special order is required when cooling with sea water) 7. Regularly exhaust and clean at intervals. 8. In the cold season, and the cooler is not working, the water must be drained to avoid freezing.